Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: EN10216-2

Brand: TORICH

Standard: Din

Section Shape: Round

Place Of Origin: China

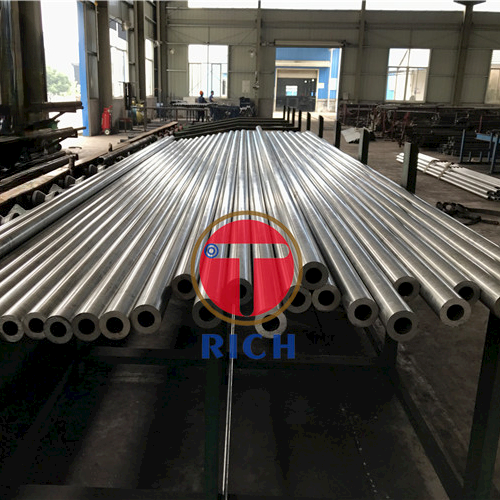

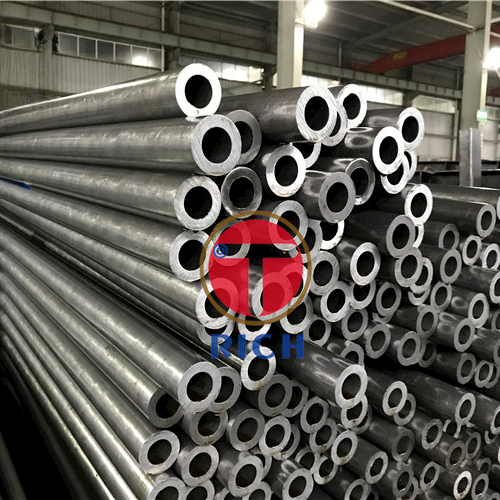

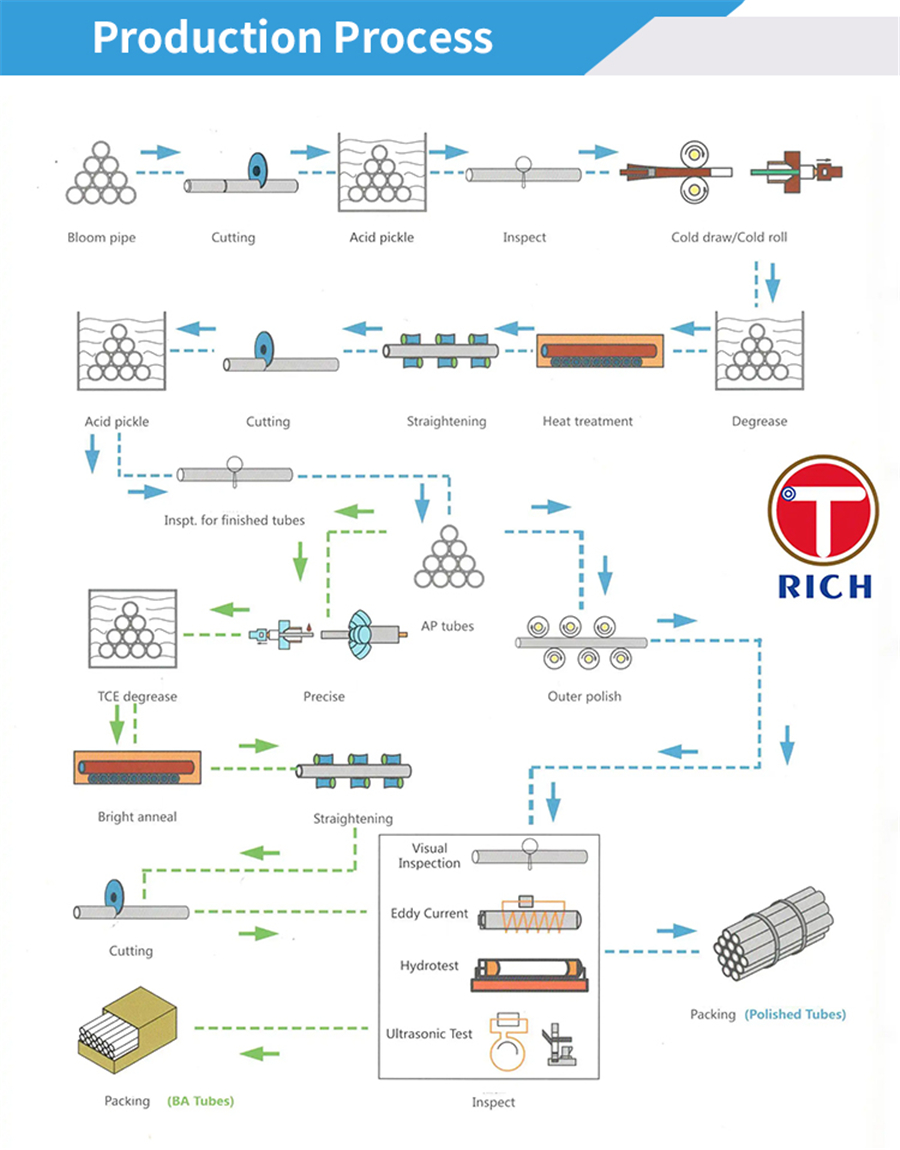

Production Process: Cold Drawn

Whether Alloy: Is Alloy

Tolerance: ±5%

Category: Seamless Steel Pipe

Processing Service: Bending, Welding, Decoiling, Punching, Cutting

Keyword: Pressure Purposes Steel Tubes

End Protector: Reqeust

Standard: DIN EN 10216-1-2004

Grade: 10#-45# Q195-Q345

Secondary Or Not: Non-secondary

Technique: Cold Drawn

O.D: 5-420mm

W.T: 0.5-50mm

Packaging: Steel bundle, Woven bag or acc. To customers' request

Productivity: 10000 Ton/Tons per Month

Transportation: Ocean

Place of Origin: zhejiang/China

Supply Ability: 10000 Ton/Tons per Month

Certificate: ISO9001 ISO14001

HS Code: 73044190

Port: shanghai,nignbo

Payment Type: L/C,T/T,D/P,D/A,Paypal,Others

The EN10216-2 standard covers the technical delivery conditions for seamless steel tubes made of non-alloy and alloy steels. These tubes are intended for use in elevated temperature applications. The cold drawn manufacturing process ensures excellent dimensional accuracy and improved mechanical properties.

The chemical composition of EN10216-2 cold drawn alloy steel tubes varies depending on the specific steel grade. Here is a table outlining the typical chemical composition for different grades:

| Steel Grade | Chemical Composition (%) |

|---|---|

| 16Mo3 | C: ≤0.12, Si: ≤0.35, Mn: 0.40-0.90, P: ≤0.025, S: ≤0.010, Cr: 0.30-0.70, Mo: 0.25-0.35 |

| 13CrMo4-5 | C: ≤0.17, Si: 0.35-0.65, Mn: 0.40-0.80, P: ≤0.025, S: ≤0.010, Cr: 0.70-1.15, Mo: 0.45-0.65 |

| 10CrMo9-10 | C: ≤0.12, Si: ≤0.35, Mn: 0.40-0.80, P: ≤0.025, S: ≤0.010, Cr: 2.00-2.50, Mo: 0.90-1.10 |

EN10216-2 cold drawn alloy steel tubes exhibit excellent mechanical properties, which make them suitable for various applications. The following table presents the typical mechanical properties for different steel grades:

| Steel Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Impact Energy (J) |

|---|---|---|---|---|

| 16Mo3 | 440-590 | ≥280 | ≥22 | ≥27 |

| 13CrMo4-5 | 440-590 | ≥290 | ≥22 | ≥27 |

| 10CrMo9-10 | 450-600 | ≥280 | ≥22 | ≥27 |

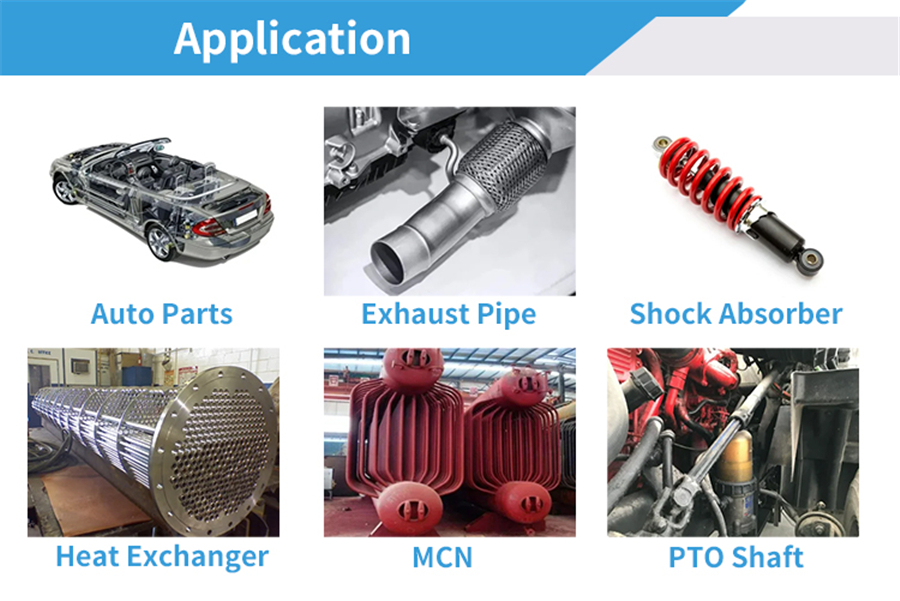

EN10216-2 cold drawn alloy steel tubes are available in various steel grades to suit different application requirements. Here are some commonly used grades and their applications:

16Mo3: This steel grade is commonly used for manufacturing heat exchangers, boilers, and pressure vessels operating at elevated temperatures.

13CrMo4-5: It is suitable for applications involving high-temperature service, such as power generation equipment, steam boilers, and pipelines.

10CrMo9-10: This steel grade finds application in power plants, petrochemical plants, and refineries due to its high-temperature resistance and corrosion resistance.

In addition to the previously mentioned grades, EN10216-2 cold drawn alloy steel tubes are available in several other steel grades, each catering to specific applications. Here are a few more grades and their corresponding applications:

14MoV6-3: This grade is commonly used in the production of power plant equipment, such as steam turbines and superheaters, where high-temperature resistance and creep strength are required.

X10CrMoVNb9-1: Primarily used in the construction of advanced power plants and high-pressure steam boilers, this grade offers exceptional resistance to corrosion, oxidation, and high-temperature environments.

X20CrMoV11-1: Suited for applications involving the manufacturing of heat exchangers, reactors, and pressure vessels, this grade offers excellent creep resistance and high-temperature strength.

X11CrMo5+I: Known for its good weldability and resistance to high-temperature corrosion, this grade is widely used in industries such as petrochemical, chemical, and power generation.

A: manufacturer,also can do trading.

A: Generally speaking,it is 10-15 days if the goods are in stock,or it is 30-40 days if the goods are not in stock, it is according to quantity.

A: Yes, we could offer the sample for free charge but need pay the cost of freight.

A: Payment<=2000USD, 100% in advance. Payment>=2000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact with me.

Product Categories : Seamless Steel Tubes

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.