Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: EN10217-1

Brand: Torich

Usage: Construction & Decoration

Type: Welded

Technique: ERW

Material: Carbon Steel

Surface Treatment: Black

Section Shape: Round

MTC: EN10204 3.1 B

Standard: EN10217-1

Production: HFW SAW

Grade: Carbon Steel

Packaging: In bundles with seaworthy packing

Productivity: 50000tons/y

Transportation: Ocean,Land,Air,by courier

Place of Origin: China

Supply Ability: 50000tons/y

Certificate: ISO9001:2008

HS Code: 7306309000

Port: Shanghai,Shanghai

Payment Type: L/C,T/T,D/P,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,FCA,CPT

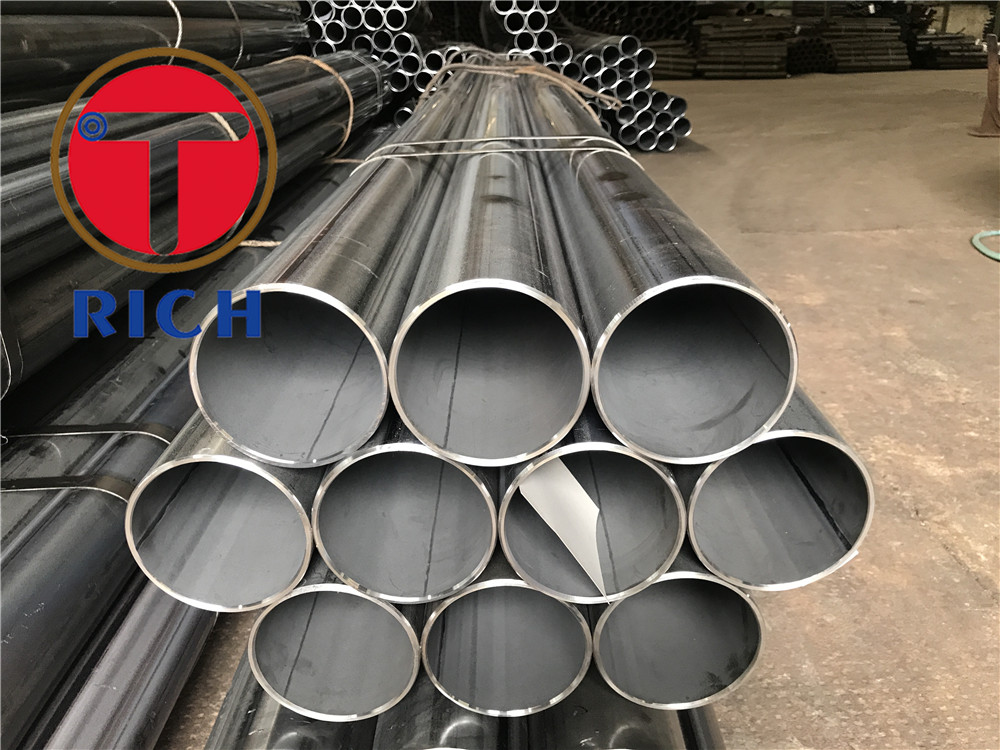

Welded Steel Tubes EN10217-1 P195TR1 P235TR1 P265TR1 for Pressure Purposes

EN10217-1 Welded steel tubes for pressure purposes - Technical delivery conditions -

China Welded Steel Pipe manufacturer, choose the high quality Spiral Welded Steel Pipe, High Frequency Welded Steel Pipe, Black Carbon Steel Welded Pipe, Oval steel tube etc.

Part 1: Non-alloy steel tubes with specified room

temperature properties

Since 2nd century, the welding seam quality increased a lot with fast development of excellent quality steel coil production, welding technology and inspection technology improvement, more welding steel tube sizes are available, and gradually widely used in different areas to replace seamless steel tube.

Material:

Fully killed steel, Fine grain steel with a ferritic grain size.

Steel Names:

In accordance with EN10027-1 and CR10260

Manufacture:

HFW High frequency welded

SAW Submerged arc welded - longiditudinal seam - SAWH

- helical seam - SAWL

Welding Procedure:

Testing and inspection of the welding procedure for submerged ard welded(SAW) tubes are witnessed and approved in accordance with EN10217-1

Apperance and General:

The weld areas are free from cracks, lack of fusion and lack of penetration

The tubes are free from external surface defects that can be detected by visual examination.

Leak-tigthtness:

The Tubes shall pass a hydrostatic test or electromagnetic test for leak-tightness

Non-Destructive Testing:

The full length of the weld seam of all EW and BW tubes ahll be subjected to a Non-Destructive test for detection of longitudinal imferfections

The full length of the weld seaml of all SAW tubes shall be subjuected to a Non-Destructive test for the detection of imperfections.

Straightness:

The deviation from straightness, of any tube length L, shall not exceed 0.0015L.

Deviations from Straightness over any one meter length shall not exeed 3mm.

Preparation of ends:

Tubes shall be delivered with square cut ends. The ends shall be free from excessive burrs.

Testing and inspection of the welding procedure for submerged arc welded (SAW) tubes in accordance with EN10217-1AnnexA

Testing and inspection of the welding procedure for SAW tubes witnessed and approved in accordance with EN10217-1 AnnexA

Tube Manufacturing Process, route and delivery condition:

| Rounte No. | Manufacturing Process | Manufacturing routes | Delivery condition | Applicable for quality | |||

| Process | Symbol | Starting material | Forming operation | TR1 | TR1 | ||

| 1a | Electric welded | EW | As(hot) rolled strip | Cold formed(+welding) | As welded | X | - |

| 1b | NW | X | - | ||||

| 1c | NP | X | X | ||||

| 2a | Normalized rolled strip | As welded | X | - | |||

| 2b | NW | X | X | ||||

| 2c | NP | X | X | ||||

| 3 | As(hot)rolled or normalising rolled strip | Cold formed(+welded)+hot stretch reduced at a controlled temperature to give a normailsed condition | NR | X | X | ||

| 4 | Cold Rolled + streass relieved | Cold formed(+welded) | NP | X | X | ||

| 11a | Submerged arc-welded -Longitudinal seam or -helical seam | SAW: -SAWL -SAWH | As(hot) rolled plate or strip | Cold formed(+welded) | As welded | X | - |

| 11b | NW | X | - | ||||

| 11c | NP | X | X | ||||

| 12a | Normaliseing rolled plate or strip | Cold formed(+welded) | As welded | X | X | ||

| 12b | NW | X | X | ||||

| 12c | NP | X | X | ||||

| 13a | As in lines 11 or 12 | Normalising formed(+welded) | As welded | X | X | ||

| 13b | NW | X | X | ||||

| 13c | NP | X | X | ||||

| 21 | Continous welded, only for steel grades P195 and P235 with D ≤114.3mm | BW | As(hot) rolled strip | Hot formed(+welded) | As welded | X | - |

| a As wekded = no heat treatment. NP=Full pipe normalsed. NW= Normalised weld zone. NR=Normaised rolled b For tubes of quqality TR2, only high-frequency welding, minimum frequency 100kHz,(symbol=HFW) is permited | |||||||

Product Categories : Welded Steel Pipe

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.