Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: GOST 9940

Brand: Torich

Type: Seamless

Certification: UL

Application: Fluid Pipe

Section Shape: Round

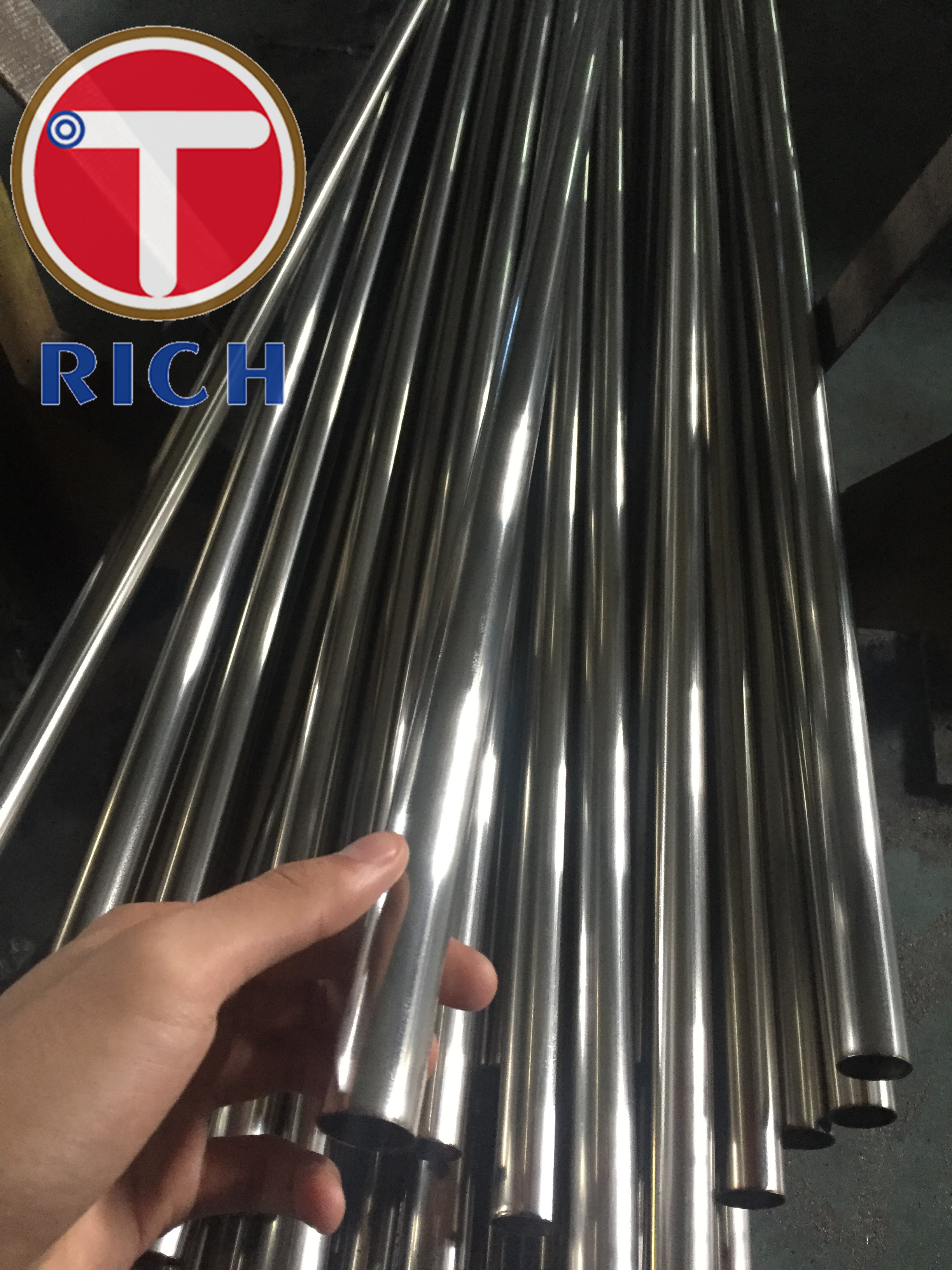

Surface Treatment: Polished

Usage: Construction & Decoration

Technique: Hot Rolled

Material: 200 Series/300 Series/400series

Finish: Heat Treatment

Shape: Round Section

Surface: Pickling

OD: 3-420mm

Length: Customers' Request

Product Name: GOST 9940 Seamless Hot-finished Steel Tu

Grade: 08Cr17Ti , 08Cr18Ni10 , 08Cr18Ni10Ti ,

Packaging: packing in wooden boxes or in hexagonal bundles

Productivity: 20000 Tons per Year

Transportation: Ocean,Land,Air

Place of Origin: Zhejiang, China (Mainland)

Supply Ability: 60000 Ton per year

Certificate: ISO9001:2008 ISO14001:2008, TS16949, CE PED, TUV, API

HS Code: 7306301100

Port: Shanghai,Ningbo

Payment Type: L/C,T/T,D/P,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,FCA,CPT

China Stainless Steel Tube manufacturers, our Stainless Steel Exhaust Tube, Welded Steel Tube, Round Stainless Steel Pipe, Polish Stainless Steel Tube, Stainless Coiled Tube, Duplex Stainless Steel Tube are good in quality and competitive in price.

GOST 9940 Seamless Hot-finished Steel Tubes of Corrosion-resistant Steel Application : For pipelines for aggressive media,as semiproducts for pressure vessels and structures,High-Temperature, Aggressive media Stainless Steel Grades: 08Cr13, 08Cr17,12Cr13, 12Cr17, 15Cr28, 15Cr25Ti, 04Cr18Ni10, 10Cr23Ni18, 08Cr17Ni15Mo3Ti, 08Cr18Ni10, 08Cr18Ni10Ti, 08Cr18Ni12Nb, 08Cr18Ni12Ti, 08Cr20Ni14Si2,10Cr17Ni13Mo2Ti, 12Cr18Ni9, 12Cr18Ni10Ti, 12Cr18Ni12Ti, 17Cr18Ni9, 08Cr22Ni6Ti Size: O.D. : 76-159mm W.T. : 5-26mm Tolerances: OD:Ordinary accuracy ± 1,5%, High accuracy ± 1% Wall Thickness: WT 5 - 8 mm: ordinary acc. +20% -15%; high acc. +12,5% - 15% WT 8,5 - 20 mm: ordinary acc. ± 15%; high acc. +12,5% - 15% WT 21 - 26mm: ordinary acc. +12,5% -15%; high acc. ± 12,5% Shipment Chemical Compositions: GOST 12344-88 GOST 12346-78 GOST 12347-88 GOST 12348-88 GOST 12365-84 GOST 20580-81 Inter-crystalline corrosion test: GOST 6032-89 1~ Incoming Raw Material Inspection 100% of our steel tubes are dimensionally checked FAQ Q: Are you trading company or manufacturer ?

Tube Sizes OD, mm WT, mm OD, mm WT, mm 76 5 - 10 127 6 - 22 83; 89; 95; 102; 108; 114 5 - 12 133; 140; 146; 152; 159 6 - 26 121 6 - 20

Mechanical Properties Steel Grade Tensile Strength, N/mm2(min) Yield Strength, N/mm2(min) Elongation, % (min) 08Cr17Ti 372 - 17 08Cr18Ni10 510 - 40 08Cr18Ni10Ti 510 - 40 08Cr18Ni12Ti 510 - 40 08Cr22Ni6Ti 588 - 24 10Cr17Ni13Mo2Ti 529 - 35 10Cr23Ni18 491 - 37 12Cr13 392 - 21 12Cr18Ni10Ti 529 - 40 12Cr18Ni12Ti 529 - 40 15Cr25Ti 441 - 17

Chemical Composition (%, max) Steel Grade C Si Mn Cr Ni Mo S P Ti V 08Cr17Ti 0,08 0,8 0,8 16-18 - - 0,025 0,035 5*C-0,8 - 08Cr18Ni10 0,08 0,8 2 17-19 9-11 - 0,02 0,035 - - 08Cr18Ni10Ti 0,08 0,8 2 17-19 9-11 - 0,02 0,035 5*C-0,7 - 08Cr18Ni12Ti 0,08 0,8 2 17-19 11-13 - 0,02 0,035 5*C-0,6 - 08Cr22Ni6Ti 0,08 0,8 0,8 21-23 5,3-6,3 - 0,025 0,035 5*C-0,65 - 10cr17Ni13Mo2Ti 0,10 0,8 2 16-18 12-14 2-3 0,02 0,035 - 5*C-0,7 10Cr23Ni18 0,10 1 2 22-25 17-20 - 0,02 0,035 - - 12Cr13 0,09-0,15 0,8 0,8 12-14 - - 0,025 0,030 - - 12Cr18Ni10Ti 0,12 0,8 2 17-19 9-11 - 0,02 0,035 5*C-0,8 - 12Cr18Ni12Ti 0,12 0,8 1-2 17-19 11-13 - 0,02 0,03 0,5-0,7 - 15Cr25Ti 0,15 1 0,8 21-37 - - 0,025 0,035 5*C-0,9 -

QUALITY CONTROL

2~ Raw Material Segregation to avoid steel grade mix-up

3~ Heating and Hammering End for Cold Drawing

4~ Cold Drawing and Cold Rolling, on line inspection

5~ Heat Treatment, +A, +SRA, +LC, +N, Q+T

6~ Straightening-Cutting to specified length-Finished Measuring Inspection

7~ Machanical Testing in own labs with Tensile Strength, Yield Strength, Elongation, Hardness, Impact, Mictrostruture etc

8~ Packing and Stocking.

100% of our steel tubes are visually checked to assure they have a perfect surface condition and no surface defects.

100% eddy current test and ultrosonic test to eliminate longitudinal and transversal defects.

A: A professional steel pipes materials inventor, manufacturer and solution provider

Q: How long is your delivery time?

A: Generally it is 7-14 days if the goods are in stock. or it is 30-60 days if the goods are not in stock, and it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but you need to pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance , balance before shippment.

If you have another question, pls feel free to contact us

Product Categories : Stainless Steel Pipe

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.