Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: ASTM B168

Brand: Torich

Type: Nickel Pipe

Powder: Not Powder

Packaging: Packed in bundles in boxes

Productivity: 25 tons per month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 25 tons

Certificate: ISO,CE

Port: Shanghai,Ningbo

Payment Type: L/C,T/T,D/P,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,EXW,FCA,CPT

Specification for Nickel-Chromium-Iron Alloy (UNS N06600, N06601, N06603, N06690, N06693, N06025, N06045, N06696) and Nickel Chromium-Cobalt-Molybdenum Alloy(UNS N06617) Plate,Sheet, and Strip

Introductrion:

Referenced ASTM Standard:

B166 Specification for Nickel-Chromium-Iron Alloy (UNS N06600, N06601, N06603, N06690, N06693, N06025, N06045, N06696),

Nickel-Chromium-Cobalt-Molybdeum Alloy (UNS N06617) and Nickel-Iron-Chromiun-Tungsten Alloy (UNS N06674) Rod, Bar and Wire.

B 880 Specification for general requirements for Chemical check analysis limits for Nickel, Nickel alloys and Cobalt alloys.

E 8 Test method for tension testing of metallic materials.

E10 Test method for brinell hardness of metallic material.

E 18 Test methods for rockwell hardness and rockwell superficial hardness od metallic materials.

E 29 Practice for using significant digits in test data to determine conformance with sprcifications.

E38 Methods for Chemical Analysis of Nickel-Chromium and Nickel-Chromium-Iron Alloy.

E 112 Test Methods for determining the average grain size.

E140 Hardness conversion tables for metal.

E527 Practice for numbering metals and alloys in the unified numbering system (UNS)

E 1473 Test methods for chemical analysis of Nickel, Cobalt and high-temperature alloys.

F155 Method of test for temper of strip and sheet metals for electronic devices (spring-Back method)

Standard: ASTM B168

Production method:Cold-finished, hot-finished

Od: 5-420mm

Wt:0.5-50mm

length:Max 12000mm

Type: Nickel alloy steel pipes

Application: For Barge and tank truck liners, Carburizing atmospheres, Ethylene dichloride crackers

Key words:

plate; sheet; strip; UNS N06025; UNS N06045; UNS N06600; UNS N06601; UNS N06603; UNS N06617; UNS N06674; UNS N06690; UNS N06693; UNS N06696

Chemical composition:

| Item | 600 | 601 | 617 | 625 | 690 | 718 | X750 | 825 |

| C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

| Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

| Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

| P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

| S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

| Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

| Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

| Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

| Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

| Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

| Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

| Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

| Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

| Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

| B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

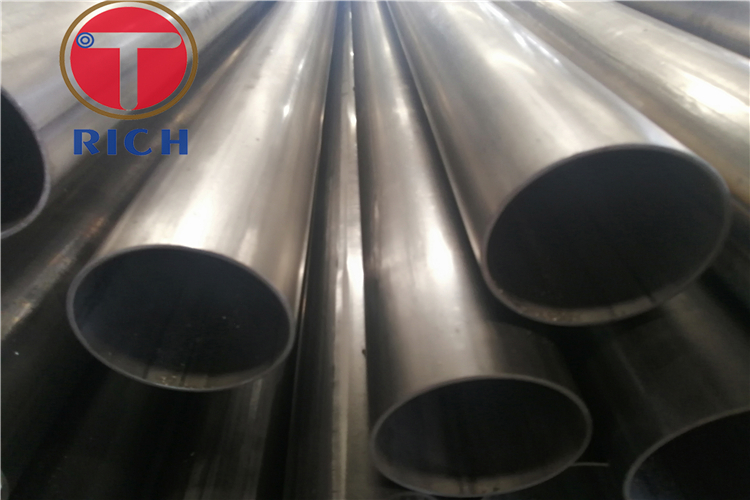

Picture:

Quality Control:

1. Incoming Raw Material Inspection

2. Raw Material Segregation to avoid steel grade mix-up

3. Heating and Hammering End for Cold Drawing

4. Cold Drawing and Cold Rolling, on line inspection

5. Heat Treatment, +A, +SRA, +LC, +N, Q+T

6. Straightening-Cutting to specified length-Finished Measuring Inspection

7. Machanical Testing in own labs with Tensile Strength, Yield Strength, Elongation, Hardness, Impact, Mictrostruture etc

8. Packing and Stocking

Product Categories : Nickel Alloy Steel Pipe

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.