Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: SA179

Brand: TORICH

Standard: Bs, Gb, Astm, Jis, Din, Api

Material: 10cr9mo1vnb, Mn-V Alloy, St35-St52, Cr-Mo Alloy, Stpg42, Q195-Q345, 10#-45#, 16mn

Section Shape: Ltz

Place Of Origin: China

Application: Fluid Pipe, Boiler Pipe, Drill Pipe, Hydraulic Pipe, Gas Pipe, Chemical Fertilizer Pipe, Structure Pipe

Surface Treatment: Copper Coated, Galvanized

Tolerance: ±10%

Category: Spiral Welded Pipe, Seamless Steel Pipe

Processing Service: Welding

Packaging: :In wooden boxes packaging+Iron frame reinforcement

Productivity: 50000 Tons/year

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 50000 Tons/year

Certificate: ISO 9001 ISO14001 TS16949

Port: Ningbo,Shanghai

Payment Type: L/C,T/T,D/P,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,EXW,FCA

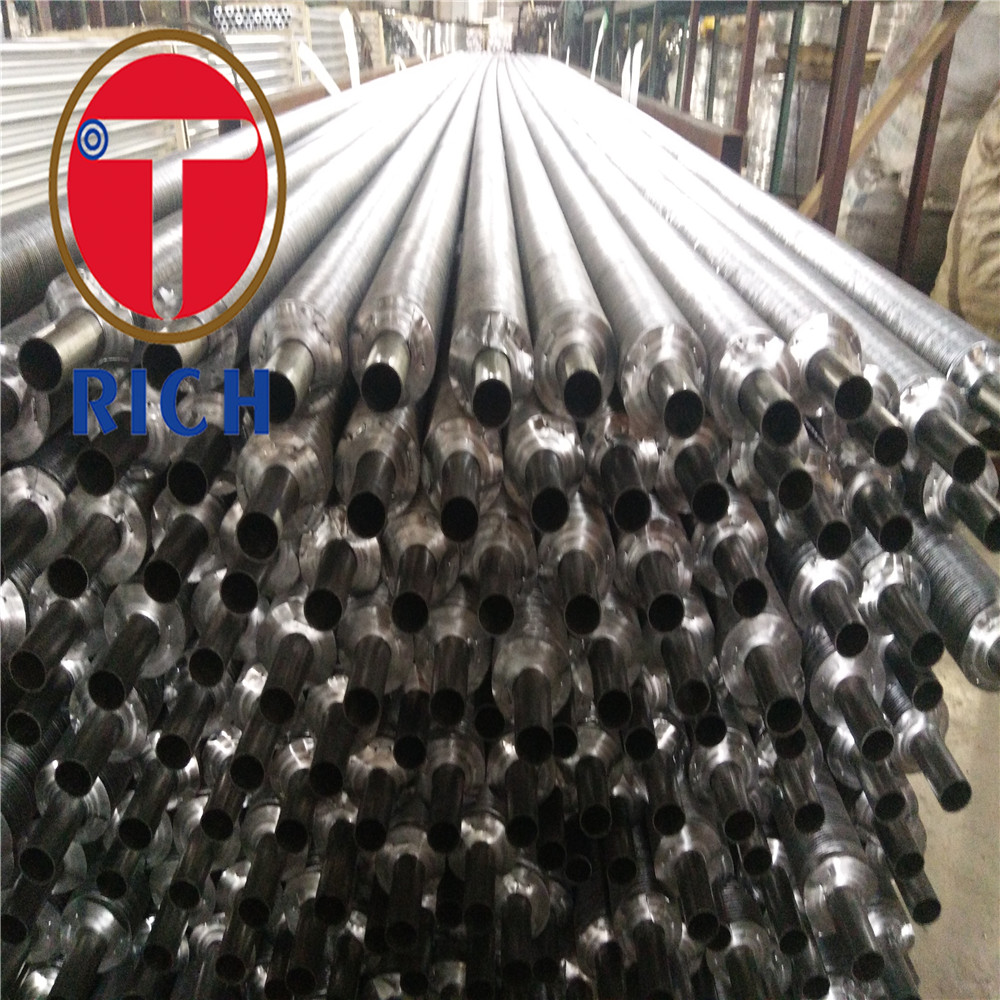

1.Introduction: Carbon, alloy steel, Stainless Steel Tube Material: carbon steel, alloy Bare tube size: O.D. 38mm-219mm Application and processing requirements of nailing head tube 一,ApplicationThe heat transfer coefficient of the flue gas side can be improved by using the nil-head tube in the convection chamber of the heating furnace in petrochemical industry. The area of the nil-head tube is 2 ~ 3 times that of the light tube. The same heat intensity can be obtained by using the nil-head tube under the condition of reasonable design 二,Manufacturing. 三, technical characteristics1, nail head specifications can be adjusted according to user needs;2. The height of the welding flesh bulge at the root of the welding nail head is about 1mm (to meet the requirements of nodular welding);3, high welding efficiency, can weld 30 nail heads per minute;4. Welding power is 160kVA; The power grid voltage is single-phase 380V.Market and economic benefit forecastNailhead tube is the main component of chemical equipment and heat exchange equipment. The production of the above equipment or equipment maintenance need to nail head pipe. Nodule - free welding is an advanced and stable technology in nay-head pipe manufacturing, which has a good prospect of effective use. PLC Program Controlling Petrochemical Industry Nailing Head Carbon Steel Tube

PLC Program Controlling Petrochemical Industry Nailing Head Carbon Steel Tube

Application Power plant boilers, heating boilers, fin economizers of industrial boilers, heat pipe air preheaters, waste-temperature boilers, and steel, petrochemical, chemical and various industrial boilers Material of base pipe

ASTM A106/A53,ASTM/ASME SA210,ASTM A213,ASTM A179/A192 Material of fins Aluminium or copper Type of base pipe Seamlesss,Welded Shape of finned tube Spiral OD of Base pipes 25mm-168 mm WT of base pipes 1-10 mm Height of fins 8mm-20mm WT of fins 0.8mm-5mm Pitch of fins 2.0mm-20mm Length of blank area According to Customer's request.

Stud size: O.D. 6mm-25.4mm

The welding process is controlled by PLC program. The feeding motor and indexing are brake motor. The man-machine interface can set the number of nail heads, indexing parameters and compensation coefficient

6. QUALITY CONTROL:

1. Incoming Raw Material Inspection

2. Raw Material Segregation to avoid steel grade mix-up

3. Heating and Hammering End for Cold Drawing

4. Cold Drawing and Cold Rolling, on line inspection

5. Heat Treatment, +A, +SRA, +LC, +N, Q+T

6. Straightening-Cutting to specified length-Finished Measuring Inspection

7. Machanical Testing in own labs with Tensile Strength, Yield Strength, Elongation, Hardness, Impact, Mictrostruture etc

8. Packing and Stocking.

6. QUALITY CONTROL:

1. Incoming Raw Material Inspection

2. Raw Material Segregation to avoid steel grade mix-up

3. Heating and Hammering End for Cold Drawing

4. Cold Drawing and Cold Rolling, on line inspection

5. Heat Treatment, +A, +SRA, +LC, +N, Q+T

6. Straightening-Cutting to specified length-Finished Measuring Inspection

7. Machanical Testing in own labs with Tensile Strength, Yield Strength, Elongation, Hardness, Impact, Mictrostruture etc

8. Packing and Stocking.

QUALITY CONTROL:

1. Incoming Raw Material Inspection

2. Raw Material Segregation to avoid steel grade mix-up

3. Heating and Hammering End for Cold Drawing

4. Cold Drawing and Cold Rolling, on line inspection

5. Heat Treatment, +A, +SRA, +LC, +N, Q+T

6. Straightening-Cutting to specified length-Finished Measuring Inspection

7. Machanical Testing in own labs with Tensile Strength, Yield Strength, Elongation, Hardness, Impact, Mictrostruture etc

8. Packing and Stocking.

100% of our steel tubes are dimensionally checked

100% of our steel tubes are visually checked to assure they have a perfect surface condition and no surface defects.

100% eddy current test and ultrosonic test to eliminate longitudinal and transversal defects.

Product Categories : Finned Steel Tube

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.